For B.E. Paton’s birthday

At the beginning of the space age, the creator of practical cosmonautics, a prominent designer of Soviet space systems Sergiy P. Koroliov, anticipating the possibility of creating large space objects of long-term action in the orbits of Earth and other planets and asteroids, believed that one of the most promising technological processes for these purposes should be bonding of materials with the use of welding technologies in space.

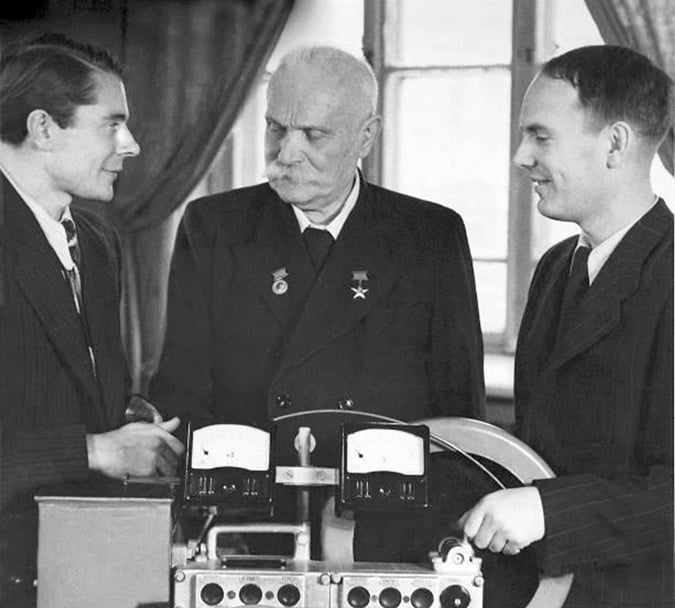

In 1964, he formulated the task to develop a series of experiments on welding in space and a plan of joint work of the “Energy” rocket and space corporation (then – OKB-1) and the E.О. Paton Institute of Electric Welding of the Academy of Sciences of the Ukrainian SSR. Soon, an unprecedented program of scientific research started under the leadership of the President of the Academy of Sciences of the Ukrainian SSR, the Director of this Institute, Borys E. Paton. Borys Paton himself became the main generator of ideas, and he was extremely interested in this issue. It is worth noting that the world’s leading space centers are still unable to reproduce some of the “Paton” technologies of welding in space.

B.E. Paton’s way towards creation of space technology was paved from the Kyiv Polytechnic Institute. And not only from its classrooms and laboratories.

“ENTERING KYIV POLYTECHNIC, IT WAS AS IF I WAS RETURNING HOME”

Borys Paton’s childhood and youth passed at Kyiv Polytechnic. He was born in the family of one of the most famous professors of the Institute, the world-famous scientist and engineer Eugene O. Paton, who lived in the professor’s house on the territory of the Institute; Borys was baptized in the Institute church of St. Mary Magdalene.

The flames of the civil war were burning in Ukraine. Educational process in the KPI one day stopped, and another day resumed, the number of students and professors halved compared to pre-revolutionary times, material conditions deteriorated catastrophically. To preserve the Institute, Eugene Paton organized a survival committee, which arranged the supply of food products from rural areas and provided assistance to those who desperately needed it. As a result, KPI professors and students and their families could survive those terrible times.

The end of the war did not bring stability either. Decrees, and sometimes violence, established new rules of life. Changes also took place at Kyiv Polytechnic. They “squeezed together” the Paton family and moved a neighbor in the professor’s apartment: he was also a KPI professor, a prominent Ukrainian mathematician and future academician Mykhailo Kravchuk. The two families lived in one apartment for more than 11 years until they moved to one of the first Kyiv cooperative houses at the corner of Liuteranska and Bankova streets, where they received separate apartments.

It is clear that from the first years Borys Paton lived in an atmosphere of technical creativity, and it identified his interests. After graduating from school, there was no doubt: the only way shall be to the Kyiv Industrial Institute (Kyiv Polytechnic was known as Kyiv Industrial Institute from 1934 to 1944). “Entering Kyiv Polytechnic, it was as if I was returning home,” Borys Paton recalled many years later. The interests of the future academician were connected with the brilliant lectures of the Academician in Mathematics Mykhailo Kravchuk, with the research conducted in the Electric Welding Laboratory of the All-Ukrainian Academy of Sciences, founded and headed by Eugene O. Paton. The now famous E.О. Paton Institute of Electric Welding of the National Academy of Sciences of Ukraine was founded on the basis of this laboratory in 1934.

Borys Paton defended his diploma project on June 22, 1941. On the way to the Institute, he and his classmates almost died, however, he defended his diploma project with honors.

Initially, Borys Paton was assigned to the Krasnoye Sormovo plant in the city of Gorky (now Nizhniy Novgorod), but in 1942 he was transferred to Nizhniy Tagil, where the Institute of Electric Welding was evacuated from Kyiv. The Institute was tasked with technological support for the production of armored vehicles, in particular the T-34. It was here that Borys Paton began to study a new engineering branch, electric welding, and soon he became a first-class specialist in this sphere.

Here, under the guidance of his father, Borys Paton took an active part in the development and implementation of automatic armor welding under flux: he developed technology, designed equipment and at the same time, performed purely scientific research. Borys Paton offered a convenient and reliable design of new automatic welding heads. The phenomenon of arc self-regulation discovered in 1942 was implemented here.

His developments formed the basis for the creation of welding machines, so that the production of tanks was put on the assembly line. In no country except the Soviet Union was automatic submerged arc welding used in the tank industry at that time. The United States began to master this method only in the last years of the war. And Borys Paton received his first order, “Badge of Honor”, in 1943.

Work on welding heads formed the basis of further research, the results of which were summarized in the PhD thesis “Analysis of welding heads and ways of feeding them during submerged arc welding”, which he defended at KPI after returning to Kyiv in 1945.

Soon Borys Paton headed one of the departments of the Institute of Electric Welding, and in 1950 he took the position of Deputy Director.

In 1952, Borys Paton successfully defended his doctoral thesis on “Study of the conditions of welding arc-burning stability and its regulation”, in KPI as well. In 1951 he was elected a corresponding member of the Academy of Sciences of the Ukrainian SSR, in 1958 – an academician of the Ukrainian Academy of Sciences in “Electric Welding”, in 1962 – an academician of the Ukrainian Academy of Sciences in “Metallurgy and Metal Technology”. In 1953, after the death of Eugene O. Paton, Borys Paton headed the Institute founded by his father.

Under the guidance of the young director and with his direct participation, research was carried out, which became the basis for creation and application of various welding methods: semi-automatic, in the environment of shielding gases, electroslag, microplasma and others. In the second half of the 50’s many new progressive developments of E.O. Paton IEW were immediately put into operation. The Institute quickly grew into a powerful scientific and technical complex, which, in addition to the research institute itself, included design and technology departments and research plants.

Soon the E.O. Paton Institute became the main research institution in the USSR for welding and special metallurgy. The “Patonivtsi” boldly undertook to solve the problems that hindered the development of entire industries, and as a result of their research, practitioners received fundamentally new ideas, inventions and ready-made technologies. In those years, the cooperation of the E.O. Paton IEW with higher educational institutions, with the Kyiv Polytechnic Institute, above all others, significantly deepened.

Therefore, it was logical that the Koroliov Design Bureau-1 began to cooperate with the Institute of Electric Welding on the implementation of the idea of welding in space.

“SPACE MAPS ARE PUT IN MAP-CASES …”

This song was sung all over the country. If someone tried to make a list of the most popular songs of the early 60’s, in the former Soviet Union, it would definitely come out on top. Probably like everything related to space.

The rapid growth of interest in space exploration was launched together with the launch of the first satellites of the Earth. Yuriy Gagarin’s flight inspired dreams of conquering the Universe. It seemed now that the stars were within human grasp, and interplanetary travel was a matter of the near future. Things that could previously be read only in science fiction, were becoming a reality. In 1964, the Moloda Gvardiya Publishing House published an unprecedented number of copies printed, 200,000, of a collection of novels by one of the founders of Soviet fiction literature, Oleksandr Beliaiev.

In the sixth volume, the novel The Star of KETs, written in 1936, was published. In the book, the idea of Kostiantyn E. Tsiolkovsky (that is why the “star” was called – KETs) about “the establishment of mobile stations outside the atmosphere” was developed in an artistic form. Beliaiev called such an orbital space station “an above-ground laboratory station and a rocket launch site for long-range interplanetary missiles”.

However, this required overcoming many scientific and technical problems.

Developers of space technology and cosmonauts of the USSR in 1969, during the launch and docking of spacecraft “Soyuz-6”, “Soyuz-7” and “Soyuz-8” worked out some elements of construction of the space station in orbit, and later created the first orbital station, “Salyut-1”, launched on April 9, 1971. In 1973, the United States launched the Skylab station as part of the Appolo program.

Such orbital laboratories were to serve for a long time and become home to many successive crews. At the same time, they were to provide opportunities for conducting complex scientific experiments in space, testing the latest space technologies. One of them was the technology of welding of durable and hermetic integral joints in space for repair and assembly of structures both inside spacecraft and in outer space.

Until the early 60’s, scientists and engineers believed that welding in space was impossible. Because outside the Earth’s atmosphere there are significant changes in temperature: the difference between them on the illuminated side of the spacecraft and in the shadows can reach 280 degrees; in addition – the absence of gravity, deep vacuum and, as a consequence, the unlimited rate of diffusion of gaseous substances from the welding zone. The conditions of the spacecraft make the experiment a little easier, but not much.

However, the staff of the Paton Institute of Electric Welding approached the task of the General Designer with great enthusiasm. Borys E. Paton personally supervised the research and development of space welding equipment.

Experimental studies were conducted in many areas: arc welding by fusion, arc and plasma, welding with and without additives; electron beam welding; diffusion welding; gas and gas-pressing welding; cold welding; soldering and welding of dissimilar metals, etc. Borys Paton (at that time he was already the President of the Academy of Sciences of the Ukrainian SSR), twice or thrice a week came to the newly founded Space Technology Unit and carefully monitored and directed the progress of work. Detailed analysis showed that the most promising for use in space are low pressure arc welding and a melting electrode; electron beam welding and contact spot welding.

It was needed not only to develop new space technologies but also test them. In order to reproduce the conditions of weightlessness, a flying laboratory was used, namely, a Tu-104 aircraft. It was equipped with special testing units, consisting of vacuum chambers, mechanical forvacuum and sorption-getter high-vacuum pumps, film cameras, oscilloscopes, control equipment, accelerometers and power supplies.

Equipment for welding with electron beam or compressed low pressure arc was installed on top of one chamber, and the mechanism for feeding thin fusible titanium, aluminum or stainless-steel electrodes was mounted on the top of the other one. The aircraft was based in the city of Zhukovsky, near Moscow, but for the safety of residents of the neighboring settlements, experiments were conducted over the Meshchersky Reserve in Riazan region. In order to create the effect of microgravity, the plane zoomed, that is rose steeply up, and then nosedived rapidly. For three tens of a second there was an effect of weightlessness in the cabin. IEW staff turned on the equipment and performed the necessary manipulations. Everything was recorded by film cameras and devices. The plane dived five times in each flight, and a total of 50 experiments were performed.

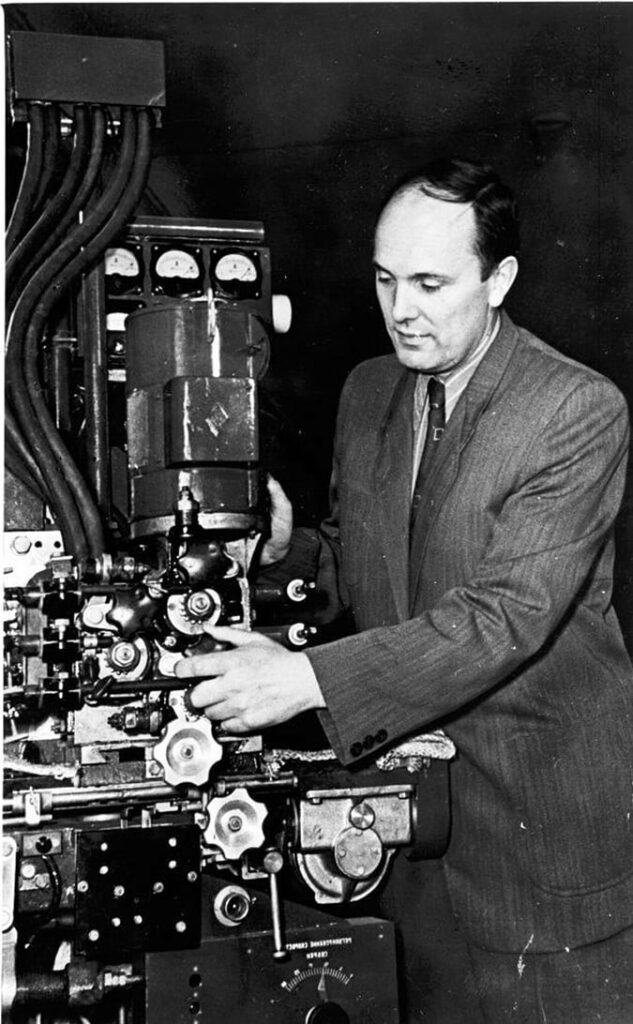

The data obtained during tests in the aircraft, as well as in course of experiments in the ground pressure chamber, were used in order to create a unique experimental automatic welding facility “Vulkan”, designed to operate in space. It allowed welding of metal parts using each of three different methods: arc, plasma and electron beam.

FOR THE FIRST TIME IN THE WORLD!

On October 17, 1969, a short TASS report appeared in all Soviet newspapers: “Yesterday, October 16, Soviet astronauts performed welding experiments on board the Soyuz-7 spacecraft.”

Mykola Kamanin, Lieutenant General of Aviation, a long-time Head of the Yu. Gagarin Cosmonaut Training Center and assistant Commander-in-chief of the USSR Air Force for space, spoke about these experiments in his book “Pilots and Astronauts”.

“… On October 16 the crew of the Soyuz-6 spacecraft conducted an interesting, unique experiment. The crew had the task to perform welding operations in space. It was necessary to find out the peculiarities of welding different metals in a space vacuum…

The Commander of the spacecraft G.S. Shonin reported readiness for the experiment. The permission was given. Soon he reported that the manhole was closed and the orbital compartment was depressurized on the 77th turn. Flight engineer V.M. Kubasov switched on the welding equipment and alternately performed several types of automatic welding… »

In his report on this experiment, Mykola Kamanin did not mention the dramatic situation, which miraculously did not happen.

Much later, Valery Kubasov himself said in an interview: “… I was commissioned to perform the first experiment on welding metal in space… The spacecraft consisted of a launcher and an orbital compartment. We were in the launcher, and the welding machine was in the orbital compartment. The compartment had to be sealed to produce a vacuum. I turned on different types of remote-control welding. When we finished the experiment and returned to the orbital compartment, I smelled a strange odor and saw a melted trace on the hull of the spacecraft 20-25 cm long. Naturally, we were scared because we were without spacesuits, and the hull could burst. I had to reduce the pressure to go back for the samples. I opened the hatch, quickly went in alone and took samples. When we reached the Earth contact zone, I reported what had happened. An instruction came to close the hatch between the compartments and not to go there anymore, and we obeyed this order.”

Probably, only Borys Paton was fully aware of all the risks of working with molten materials in space flight and understood what surprises may occur despite all preliminary calculations. Sergiy Koroliov’s longtime deputy, Borys Chertok, recalled how on the day of the experiment, Paton was walking up and down along the path near the Flight Control Center, ignoring the magical colors of the mild Crimean autumn. (The Center was then located in Evpatoria.)

The excitement was caused by the fact that the first welding in orbit was carried out not by a specialist, but by an astronaut, albeit trained in the techniques of working with welding equipment. Despite the fact that there was a real opportunity to send a representative of the Paton Institute on this flight, Borys Paton agreed it with Sergiy Koroliov at one time. Then a group of 10 candidates was formed at the Institute, they were sent to a special medical commission at the Central Military Hospital in Moscow. After several testing stages, seven were dropped out. Eventually, Volodymyr H. Fartushny, a senior researcher, PhD in technical sciences, KPI graduate (later a long-time Head of the Society of Welders of Ukraine) was enrolled at the cosmonaut detachment. He successfully passed all training stages and was appointed cosmonaut-researcher from the Eugene Paton IEW. But, unfortunately, Vasily P. Mishin, who headed the OKB-1 after Sergiy Koroliov’ death, decided that test cosmonaut Valery Kubasov will conduct the first welding experiments in space.

No matter how, this experiment proved that automatic welding and cutting of metals in space is quite possible, and the most suitable is electron beam technology.

IN OPEN SPACE

The next stage was the development of equipment for manual welding and metal cutting in open space. IEW scientists, engineers and technicians began to think about such a tool while working on the Vulcan facility. With its help, the astronaut had to carry out repair or installation work both inside and outside the spacecraft.

After numerous experiments in the laboratory, in the pressure chamber and the aircraft, a complex of universal electron-beam hand tools (URI) was developed in the IEW. All its elements and components (working tools in a special lodgment, cables, secondary power supply unit) were placed in a container-backpack measuring 400x450x500 mm, which could be carried shoulder-high or attached to the surface of the spacecraft. A sample case with samples of materials for welding, soldering, cutting and coating was also fitted to the container. The URI weighed about 30 kilograms, and, additionally, the electron beam gun weighed 2.5 kilograms.

This equipment was included in the scientific equipment of the Salyut-7 orbital station. During the operation of the station (from 1982 to 1986) 6 main crews and 5 visiting expeditions worked in it. During one of the visiting expeditions, for the first time the crew members of the spacecraft “Soyuz T-12” carried out the testing of welding equipment designed in the E.O. Paton IEW, in open space. It happened on July 25, 1984. The work was carried out by the crew commander Volodymyr O. Djanibekov and the flight engineer, the world’s second female astronaut, Svitlana Ye. Savitska.

For experiments, Volodymyr Djanibekov equipped a real welder’s workplace. “I had to do the work of a carrier, a welder and even … paparazzi, – Djanibekov later recalled, with humor. – You had to take a whole stack of things with you to outer space: a welding machine, metal samples, tele- and photo cameras. I pulled all of them, of course. This was my first extravehicular activity. I had equipment in the hands, so gripped hold of the station overhangs with my legs. Hence, it was difficult to keep the balance. Meanwhile, Svitlana anchored securely in the place designated for the experiment. She started working, and I filmed a TV report about it, then took a camera and clicked on it like paparazzi.”

First, Svitlana Savitska performed the operations of cutting, welding, soldering and coating on special samples, and then Volodymyr Djanibekov tested the URI operation in welding, cutting, soldering and coating modes with these samples. Stainless steel and titanium alloys 0.5… 1 mm thick were used for welding. The quality of the obtained joints was considered high, although during the cutting process the molten metal was poorly removed from the cuts due to weightlessness. Aluminum plates were used for silver coating application. However, no abnormal situations arose.

The work of both astronauts in outer space lasted from 14:55 to 18:29 – more than three hours and a half. The experiment showed that universal equipment designed in the E.O. Paton IEW, is quite durable and suitable for work in open space, and welding using electron-beam technology is very promising for use in space expeditions.

B.E. Paton wrote about this experiment: “Cosmonauts S. Savitska and V. Djanibekov demonstrated real heroism, taking lead in these fundamental space experiments. They have just broken the ice of distrust among skeptics who have questioned the very possibility of using welding technology in space.” Paton maintained friendly relations with Volodymyr Djanibekov and Svitlana Savitska for many years after their flight.

In 1986, cosmonauts Volodymyr Solovyov and Leonid Kizim performed the similar experiments, but within the framework of an expanded program, after the docking of the “Soyuz T-15” spacecraft with the “Salyut-7” orbital station. Later, units of the truss structures of the mechanism for solar array deployment of reusable solar panels at the Mir orbital station were soldered using the improved URI. In 1979-1989 a number of experiments were carried out on the evaporation of metals and the deposition of film metal coatings on samples of structural materials at the “Salyut-6”, “Salyut-7”, “Mir” orbital stations. The case was not limited to experiments: the “Salyut-6” station crews repeatedly restored the efficiency of its individual components by soldering.

Thus, welding technologies became the first space technologies to be used in orbit for their intended purpose. And Borys E. Paton is a real forerunner and pioneer of the space technologies era!

In the nineties, specialists of the Institute under scientific supervision of B.E. Paton created “Universal” facility – a new complex for application of electron beam technology in space. It had a replaceable tool for welding, spattering, soldering and cutting and was powered by electricity from the onboard network of the space station. The output capacity of new equipment was more than doubled. “Universal” could be used as a manual tool, or built into mechanized remote-controlled installations to restore degraded surfaces of heat shields, antennas and other facilities on space stations.

“Universal” passed the whole complex of pre-flight tests, it was certified and ready to work on the orbital station “Mir” (it was even placed on board the station). But no experiments took place: due to a number of technical problems and failures in the operation of systems and devices, the “Mir” station had to be liquidated and flooded in the Pacific Ocean in 2001.

In the next decades the IEW specialists continued to work on the development of advanced welding equipment for work in outer space. Under the B.E. Paton’s supervision, a new generation manual electron beam facility was developed, which included a triode electron beam gun separated from a high-voltage power supply unit. This design solution made it possible to significantly reduce the weight and size of the facility and at the same time, increase its maneuverability when welding in space. The weight of the gun with the handle and guard is about 3 kg, which is almost twice less compared with the “Universal”.

Despite the fact that electron beam welding was recognized as the main type of space welding, Borys Paton did not rule out the possibility of using other types. In 2000, he wrote in the paper “Welding and related technologies in space and ocean exploration. 21st century”: “… in the future arc and plasma welding and cutting will still find application in space, for example, in the construction of various objects on the Moon. It is necessary to improve both types of welding, as well as electric arc metallization. This will require serious research into the physics of arc and metallurgical processes occurring in arc welding in vacuum, under microgravity. However, now fusion welding is required in space while constructing large orbital stations and platforms, and for repair operations as well … “. Paton believed that there were no obstacles to use contact welding in space, especially because the possibility of spot welding under microgravity was tested in the sixties.

In the paper, B.E. Paton also thought a lot about the possibility of using welding and related technologies outside the Earth, and especially for large-scale long-term projects: “Various welded transformed structures manufactured on Earth are of interest. It is possible to transport them to the orbital station or to the Moon in a compact form. Shell metal structures are able to “inflate” with a small excess internal pressure and acquire a given shape and dimensions. It is possible to assemble more complex and larger structures in space combining individual transformed elements by welding. Transformed sliding structures consisting of unified units will also be used. They can be used both on orbital space stations and on the Moon. In a word, welding technologies in space are not science fiction… ». That’s the best way to say it!

BORYS PATON AND KPI

“Dear friends! I sincerely congratulate you on the 85th anniversary of the first issue of Kyiv Polytechnic newspaper… The newspaper is not alien to me: in the first years of its existence one of its authors was my father, then a professor at Kyiv Polytechnic Institute Eugene O. Paton. I read it since I was a student. So even today I always open fresh issues of the newspaper with interest and join the life of my Alma Mater”, these words are from Borys Paton’s congratulations on the anniversary of the Kyiv Polytechnic newspaper. They reflected his attentive and friendly attitude to any notable event related to the KPI.

Borys Paton learned about the news of the University not only from the University newspaper, because his scientific and scientific-organizational activities were closely related to the activities of Kyiv Polytechnics. The E.O. Paton Institute of Electric Welding, headed by him, fruitfully cooperates with the University’s professors and scientists for many decades. And B. Paton himself often visited the KPI, not only its scientific departments, but also as participant at conferences, sessions, solemn events, meetings, etc. Kyiv Polytechnics have always been proud of its graduate and mentor.

In 1965, Borys Paton initiated the construction of a new building for the Welding Faculty of KPI, founded by his father, and equipping its laboratories with modern equipment. In 1977, the Institute received this building with unique research laboratories. The development of the Faculty of Electric Welding gained new dynamics in the first decades of the 21st century. At the initiative of Borys Paton and with the direct participation of Academicians Kostiantyn A. Yushchenko and Igor V. Krivtsun, the latest programs in scientific research and trainings of highly qualified scientific personnel were implemented. The Faculty is accredited by the International Welding Institute as a National Training Institution for training of international welding engineers and international welding technologists. In 2020, the Faculty of Welding became one of the three subdivisions of the University, on whose basis the E.O. Paton Institute of Materials Science and Welding was founded (the second subdivision was the Faculty of Engineering and Physics, the third one was the Department of Laser Engineering and Physical and Technical Technologies of the Mechanical Engineering Institute of KPI).

The establishment of such a powerful educational and scientific formation was dictated by life: today the manufacture of new structures is quite closely linked to the creation of new materials, and new materials, in turn, require the latest welding technologies – laser, plasma, electron beam and hybrid. As a result, the merging of the two faculties into a new Institute opened up new opportunities for training and research. Borys Paton himself was very positive about such a merging and naming the newly founded Institute after his father.

… Borys E. Paton lived a dignified, happy life, full of great goals and great deeds. He left invaluable achievements, he is an example of what a real scientist, patriot, a real citizen of his country should be like.

Professors and students of the National Technical University of Ukraine “Igor Sikorsky Kyiv Polytechnic Institute” commemorate him. The memorial plaque is installed on the wall of the house where he was born. The State Polytechnic Museum at KPI is named after Borys Paton. A monument to Borys Paton is being erected near the main administrative building of the University. Like his father, whose memory is also immortalized by a monument on the territory of the KPI, Borys Paton will always meet new and new generations of Kyiv Polytechnics with hope and quiet joy that they follow in his footsteps.

Michael ZGUROVSKY, Academician of the NAS of Ukraine, Rector of NTUU ” Igor Sikorsky Kyiv Polytechnic Institute”

Svit newspaper, № 43 – 44, November 2021